Issue: The Importance of Dimensional Precision in Turbomachinery

The dimensional precision of the mid-planes of compressors, and more generally turbomachinery, is crucial for ensuring effective sealing. Any geometric non-conformities can cause process fluid leaks, often gas, leading to various issues: reduced efficiency, damage to components, and in the worst cases, serious safety risks for personnel, especially in the presence of gases contaminated with hazardous substances like hydrogen sulfide.

Localized Deformations in 2MCL Compressors

In the 2MCL compressor, the subject of our work, localized deformation of the mid-planes was detected, both in the lower and upper casing, in the Drive End area, preceding the Dry Gas Seal. In light of these deformations, the customer requested a localized restoration of the planar surfaces, relying on Nuova Simat.

Nuova Simat’s Intervention for Restoring Planarity

Use of Advanced Measuring Instruments

Nuova Simat’s contribution went beyond mere mechanical processing, including the definition of an optimal solution thanks to its equipment and expertise in the use of measuring instruments. By employing precise and versatile tools such as the Laser Tracker and Laser Scanner, it was possible to accurately identify out-of-tolerance areas, isolating non-conformity to specific zones. This approach allowed us to avoid machining the entire mid-plane, thus saving valuable time.

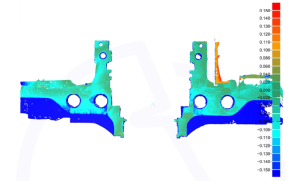

Solution of Localized Welding and Milling

The chosen solution involved localized build-up welding, followed by milling using Nuova Simat’s modular MM6000 milling machine. During the operation, the Laser Tracker was constantly used for real-time control of the restored planar surface. Upon completion, a scan of the worked areas was performed, comparing the actual geometry with the nominal one as indicated in the design, as shown in the following image.

Results of the Restoration: Guaranteed Precision and Reliability

Restoring Planarity within Tolerances

Nuova Simat’s intervention restored the planarity of the mid-planes within the design tolerances, minimizing the risks associated with the activity. This optimized strategy reduced machine downtime, allowing us to deliver the ready-to-operate machine to the customer on schedule, without additional costs. The precision and efficiency of the work ensured the success of the intervention, confirming Nuova Simat as a reliable partner for high-precision solutions.

For more information on our milling and restoration solutions, please do not hesitate to contact us.