With over 30 years of experience in on-site machining and industrial maintenance, Nuova Simat has always been at the forefront of providing innovative compressor casing repair solutions. Our Research & Development department constantly pushes the boundaries of what is possible, delivering tailor-made solutions that others had never envisioned. This success story highlights one of our recent interventions: the repair of a cracked compressor casing, a challenge that required precision machining, expertise, and advanced technology.

Step 1: Initial Survey – Detection of Needs and Critical Issues

During the initial assessment, a crack was identified on the compressor casing. The available space was analyzed, and a strategic intervention plan was developed in collaboration with the casing manufacturer. The agreed-upon approach involved machining the affected area to completely remove the crack and then installing a dowel to restore the structural integrity of the casing. This preliminary survey was crucial in defining the most effective solution.

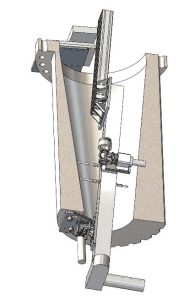

Step 2: Technical Study of the Solution – Technical Analysis and Solution Development

Following the initial assessment, our team conducted an in-depth technical study to determine the necessary equipment. Leveraging our extensive fleet of on-site machining tools, we identified a custom milling machine that could be adapted for this specific operation. Our R&D team modified the machine to fit the compressor casing and execute the required precision machining process with efficiency.

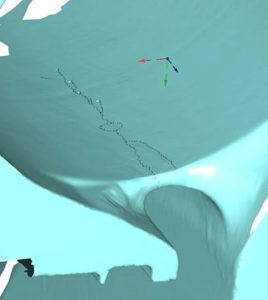

Step 3: Laser Scanning – Defining the Actual Geometry

To ensure the highest accuracy, an initial laser scan was performed before machining. This step provided a precise reference of the casing’s geometry, enabling us to restore its original shape after the intervention. The use of laser scanning technology is an integral part of our workflow, allowing us to guarantee flawless execution.

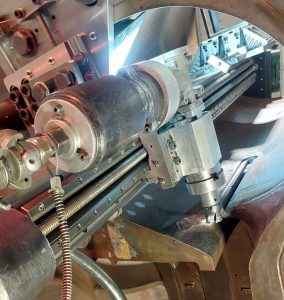

Step 4: Machining – Precision Execution

With the customized milling machine in place, the machining phase proceeded smoothly, meeting the estimated timeframe. Thanks to our skilled technicians and advanced equipment, the crack was entirely removed, paving the way for the next step of the compressor casing restoration process.

Step 5: Rapid Prototyping & Manufacturing of the Final Part

After machining, the casing was remeasured using laser scanning to determine the exact geometry of the machined slot. Based on this data, a CAD model of the dowel was created. To ensure perfect compatibility before final manufacturing, a plastic prototype was 3D printed and used as a drilling jig for the fixing holes. This rapid prototyping approach minimized errors and optimized the final installation process.

Step 6: Project Completion – Successful Installation and Validation

A trusted Nuova Simat supplier manufactured the final component, which was delivered and installed on the casing within just two days. The compressor casing repair was successfully completed, restoring the compressor casing to full operational capacity.

The Nuova Simat Difference

This project underscores Nuova Simat’s ability to develop unique and effective solutions by integrating cutting-edge technology, a highly specialized R&D team, and decades of hands-on experience. Our commitment to innovation in on-site machining and precision industrial maintenance ensures that we continue to set new standards in the field of compressor casing repair and restoration.