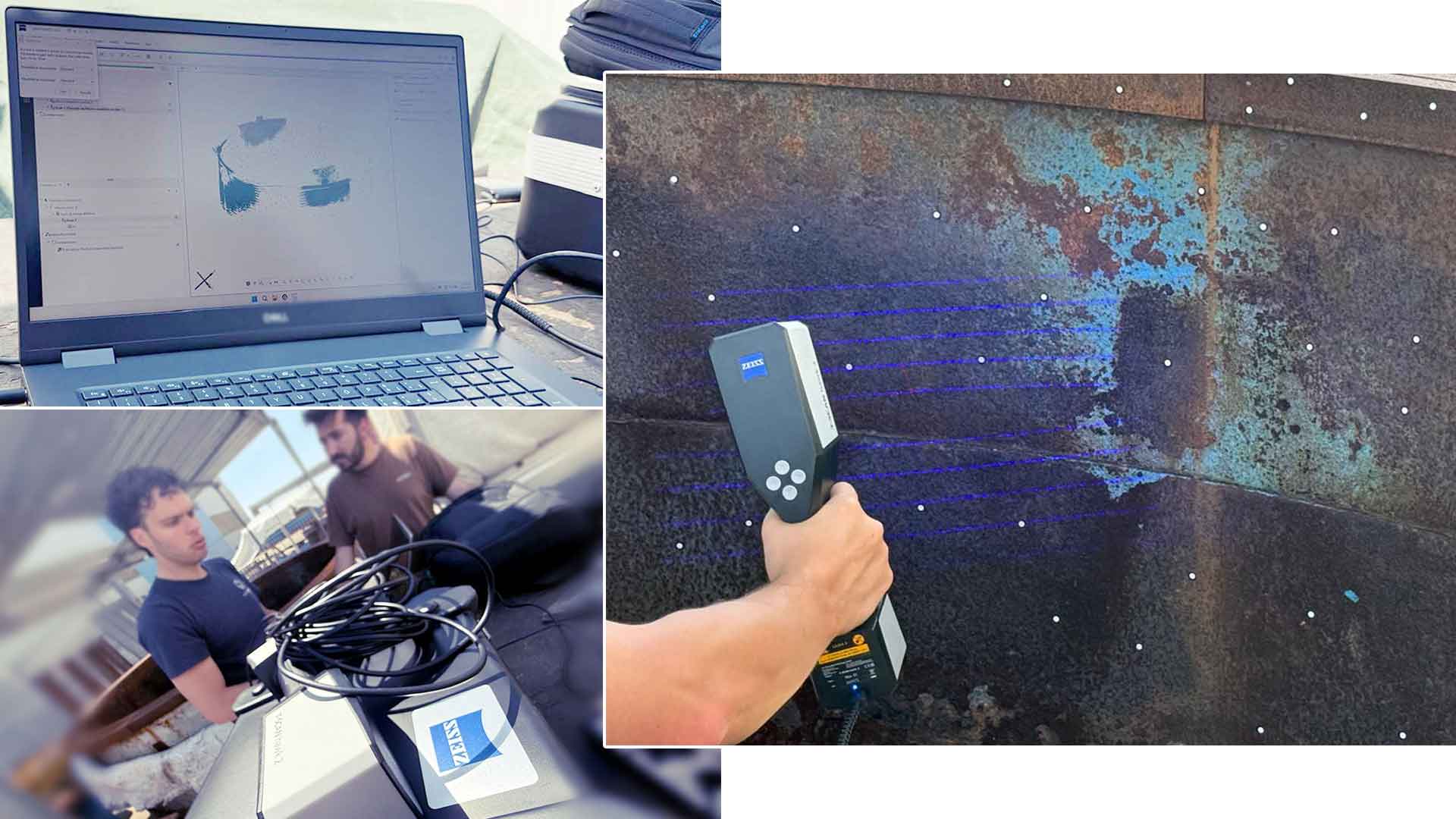

REVERSE ENGINEERING: Digital Reconstruction with Maximum Accuracy

Our reverse engineering service enables the digital reconstruction of existing mechanical components when technical drawings are unavailable.

We use the ZEISS T-SCAN Hawk 2, a high-precision portable laser scanner that quickly captures the complete geometry of objects up to over 4 meters in length. The system produces highly accurate 3D models—with precision up to 0.02 mm—ready for CAD reworking. This process is ideal for restoring worn or deformed parts, replicating discontinued components, or carrying out advanced quality control.

Scanning of large components, even in complex environments or confined spaces

Detailed capture of complex geometries and curved surfaces

CAD reconstruction and 3D modeling for manufacturing or FEM analysis

Geometric tolerance verification through comparison between real object and nominal model

Integration with other measurement systems for combined dimensional control

On-site scanning at the customer’s location—no disassembly required

Nuova Simat S.r.l. Società Benefit| Cod. Fiscale e P. IVA 01591210495 | capitale sociale € 100.000,00 i.v. | codice SDI M5UXCR1