Portable electrical discharge machining

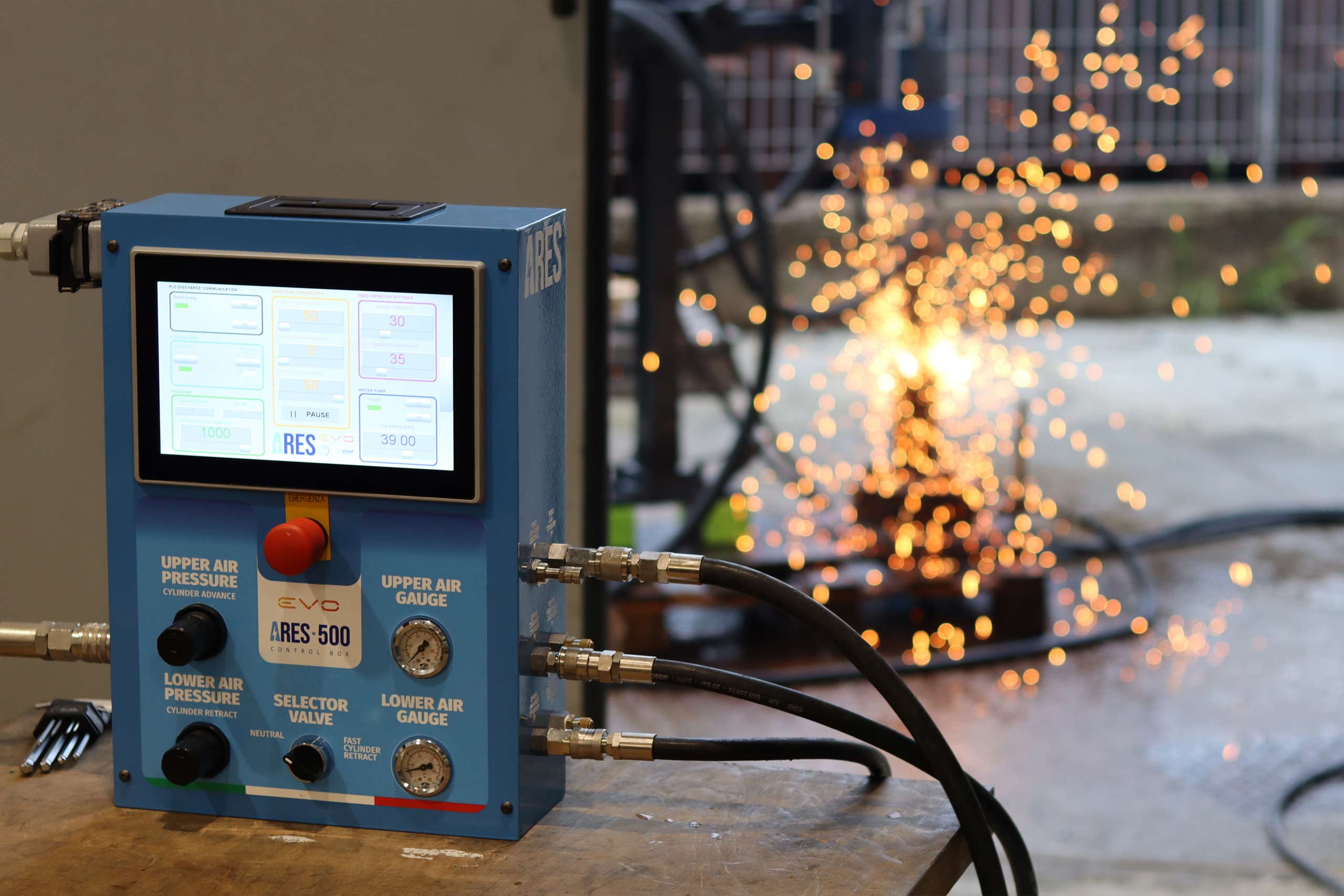

ARES-500

ELECTRICAL DISCHARGE MACHINING (EDM)

The portable solution for the removal of mechanical elements such as pins, studs, bolts, locked nuts, etc., by disintegrating very hard metals in challenging environments.

ARES-500 combines advanced electrical discharge machining (EDM) technology with a modular and portable design, making it ideal for operations in demanding environments.

Up to 10 times faster than standard drilling methods.

Whether for power plants, refineries, or heavy machinery maintenance, ARES-500 adapts to a variety of applications, offering reliability, safety, and versatility.

ARES-500 (EDM)

MAIN FEATURES

Wide

Range

of Applications

Perfect for removing stuck bolts, broken studs, pins, shaft keyways, and creating large pilot holes. Faster

than standard drilling methods, with unparalleled precision.

Intuitive Touchscreen Display

User-friendly interface for parameter adjustment and process monitoring, ensuring easy and effective

operation.

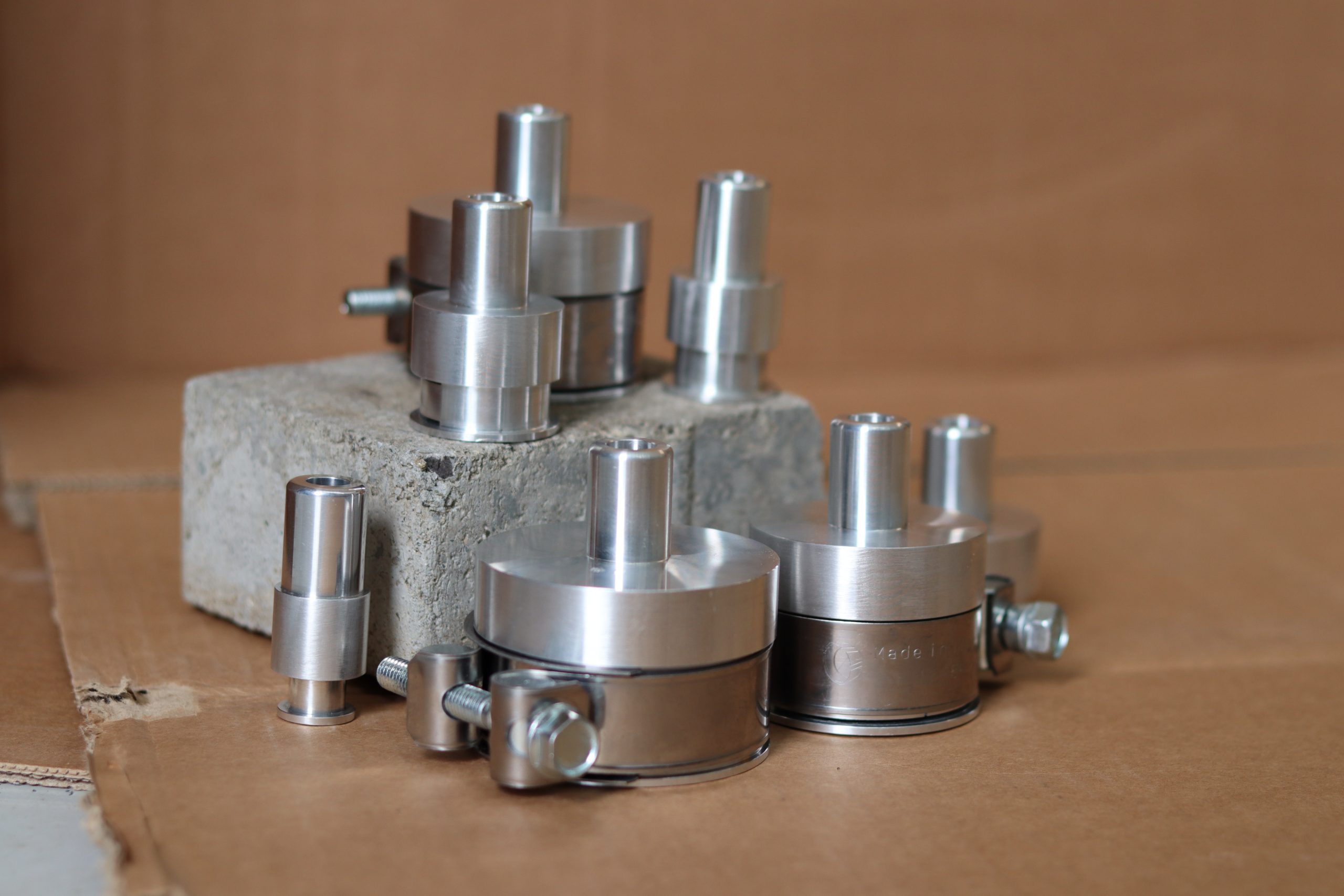

Standard and Custom Electrodes

Supports a comprehensive range of electrodes, including custom designs for specialized tasks.

Total

Finish

Control

Enables adjustments to the operating frequency, ensuring optimal performance across different materials

and conditions. To achieve all shades of finish, from gross to smooth.

Techincal specifications:

STANDARD RANGE: M6 – M200

POWER: 20 KVA

—

UTILITIES REQUIRED:

Electrical supply: 400V AC 3ph, 50-60Hz

Air: 7 bar

Water flow: 60 l/min

—

Tank campacity: 75 litri

Weight: 400 kg

ARES-500 how does it works

Portable EDM Machine ARES 500:

Fields of Application

The ARES-500 represents one of the most advanced solutions in the field of Electric Discharge Machining (EDM), combining high performance with maximum portability. Thanks to its compact structure and ease of use, this spark erosion machine is fully classified as a portable EDM machine, ideal for all applications requiring on-site operations without the need to dismantle large components.

Within the realm of electrical discharge machining, the ARES-500 is designed for the removal of seized or damaged mechanical elements on large-scale machinery such as industrial heat exchangers and marine components. It is widely applicable in the oil & gas and power generation sectors. Capable of high-precision EDM drilling, even on extremely hard or delicate materials, it is also perfectly suited for micro EDM drilling tasks in aerospace, mechanical, and energy industries.

This portable EDM is extensively used for operations such as stud removal, seized bolt extraction, and the disintegration of blocked fasteners inside complex mechanical assemblies. It is also ideal for removing jammed components from turbine casings, compressor housings, and other critical parts, where precision in material removal is essential to prevent damage to adjacent surfaces.

The ARES-500 stands out from other EDM machines for its versatility and reliability: its electric discharge machining technology allows it to work on any type of conductive metal, always ensuring maximum accuracy.

ARES-500 is therefore a cutting-edge solution among portable EDM machines, capable of delivering high-level performance even under challenging operational conditions. It is not just a portable spark erosion machine, but a strategic tool for all companies needing to work on-site with the highest levels of precision and reliability. Whether it’s removing seized studs in harsh environments or performing EDM operations in industrial plants, the ARES-500 is the ideal choice -to tackle even the most complex EDM challenges, with a wide range of applications wherever precision spark erosion machining is required.

ARES-500

To learn more about the portable electrical discharge machining (EDM) machine and discover how it can improve your machining operations, contact us today.

Our team of experts is ready to assist you and provide all the information you need to make the right decision for your business.